Custom Foam

The Strongest Exterior is Nothing

Without a Secure Interior

Anyone can do foam. We’re not just anyone.

We’re experts at matching a limitless array of foam types, fabrication methods, and case types—all while staying at your price point.

And guess what? We’re experts at making cases too. If your ideal case doesn’t exist, we can design and produce it for you.

What's the Ellis Difference?

- We can do anything.

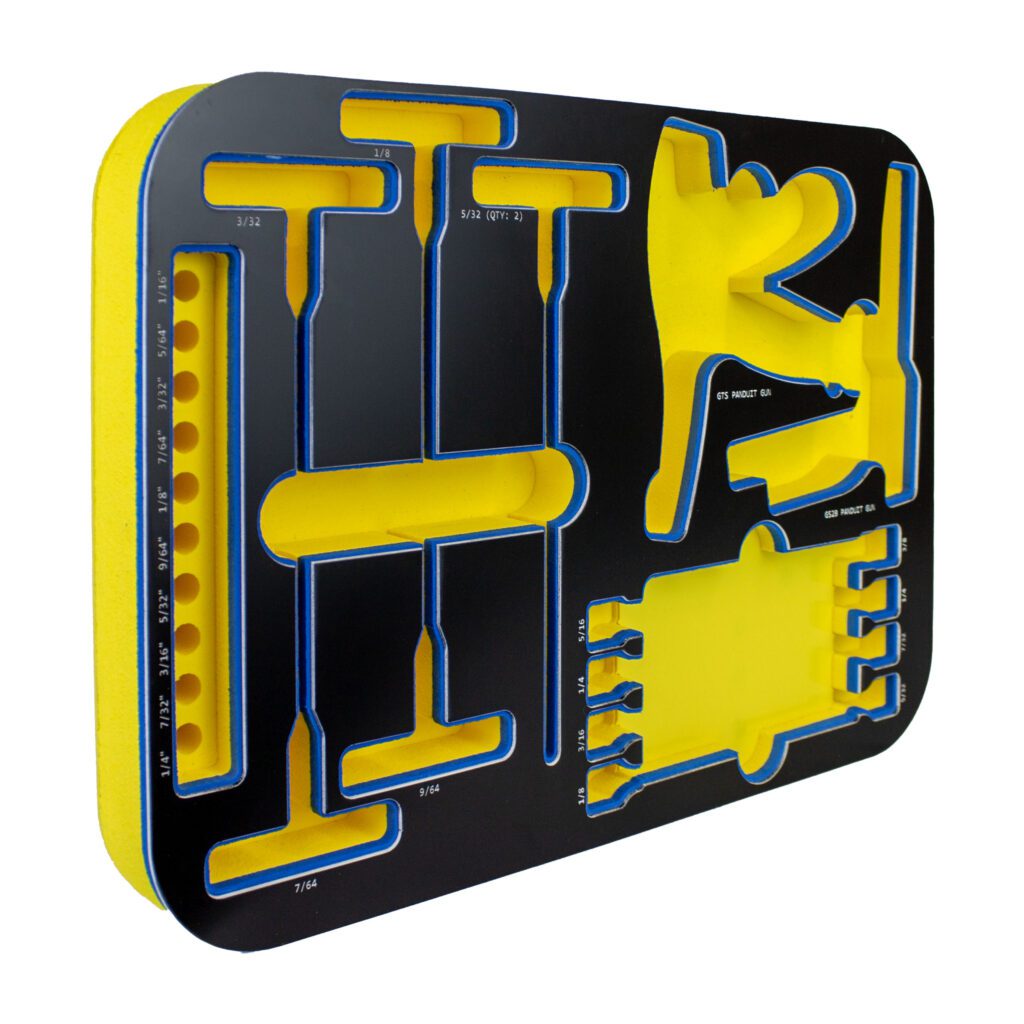

- Plank, Pick and Pluck, die cut, CNC routed, CNC knife, waterjet, glue-laminated, and heat-laminated foams.

- Our experts pick the right foam and tools to maximize value for you.

Custom Foam for what matters most

Ellis is your source, whether you need a case for surface protection and organization or full blown lab-certified shock load absorption—or something in between.

Versatility

(Closed Cell)

Protection

(Closed Cell)

Display

(Closed Cell)

Specialized Applications

(Closed Cell)

Electronics

(Closed Cell)

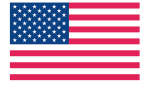

Polythylene

- A relatively firm, closed-cell foam that offers good cost performance and versatility

- Does not absorb water. Excellent shock and vibration protection

- Durable and moderately pliable. Can absorb repeated impacts and still provide cushioning

- Great for mid-weight to heavy objects that need a secure, snug fit (TVs, computers, industrial parts)

Polyurethane

- A light density, open-cell foam that provides excellent shock absorption

- Spongy and forgiving; absorbs water

- Great for more lightweight, delicate objects that may break on modest impact

Cross-Linked PE

- A dense, fine-celled, high-end version of PE with high compression resistance

- Extremely durable for long term repeated use

- Great for high-end applications that require both durability and display

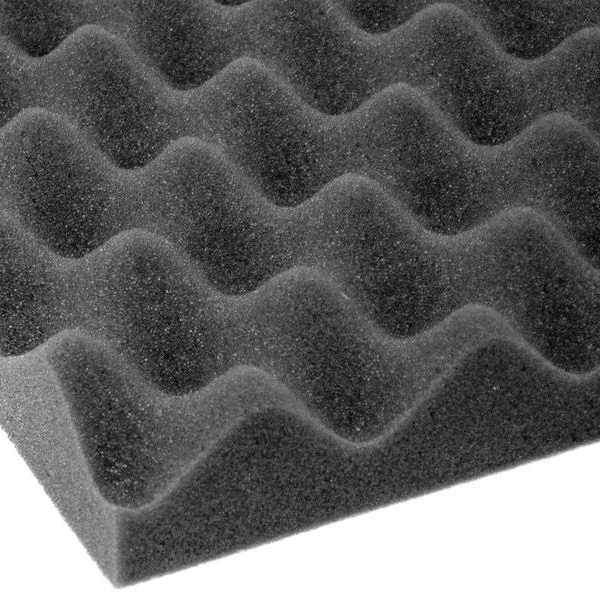

Flocked

- Felt-covered foam that provides a pop of color and texture

- Goes over any foam with multi-layered options

- A creative differentiator that’s also cost-effective

Anti-Static

- A PE type foam fabricated with ESD protection for sensitive electronic devices

The Opportunities are Endless

Custom Foam Ensures Safety, Organization, and a Great First Impression

Foam Filled

Water-Jet Cut

Combination Fabrication

Die Cut

The Design Process

Our custom foam designs provide dependable protection within a rugged, purpose-built case.

From start to finish our expert teams handle your cases with care.

Connect

Fill out our online intake form in 5-to-10 minutes, and you’ll receive a response from us within 48 hours. We’ll get started by discussing your goals, budget, and time constraints.

Get Started

Don’t know where to start? We do! We’ll help you develop your specifications as we further discuss your needs, review photos, and explore physical samples.

Value Engineering

We work hard to save you money. One way we do this is by purchasing raw materials directly from the manufacturer whenever possible. Our customer service is focused on bringing you cost efficiency and quality.

Sampling

You know that the case is a key contributor to the overall success of your program. We offer pre-production samples or first articles so you can verify that every functional and cosmetic aspect of the design matches your expectations before investing in production quantities.

Design Iteration

Show us the products or contents that will require foam and we’ll recommend the best foam insert design. Already have an idea? Send us a drawing to get started!

Performance (Engineering) Modeling

We use state-of-the-art 3D CAD software to model the perfect fit for your products in foam. Need it absolutely secure during rough transport? No problem. Want it easy to remove in a sales demo? No problem. We can provide foam deflection estimates, informal drop testing, and certification on a variety of ASTM and IEC standards.

Approval

Once you’re completely satisfied with the samples and pricing we’ve provided, simply let us know you are ready to order.

Production

At this point, our 120+ years of manufacturing experience take over to deliver you a high quality product, on time.

Need Foam fast?

Are you looking for an even faster solution for interior case foam? Is your design changing and you aren’t ready to order a fully customized foam set? We have you covered!

Check out our selection of case and foam combinations that allow you to create your own foam inserts when time or budgets are limited.

Ask us about:

- Blow-molded cases

- Stock vacuum-formed cases with plank foam

- Do-It-Yourself cubed foam

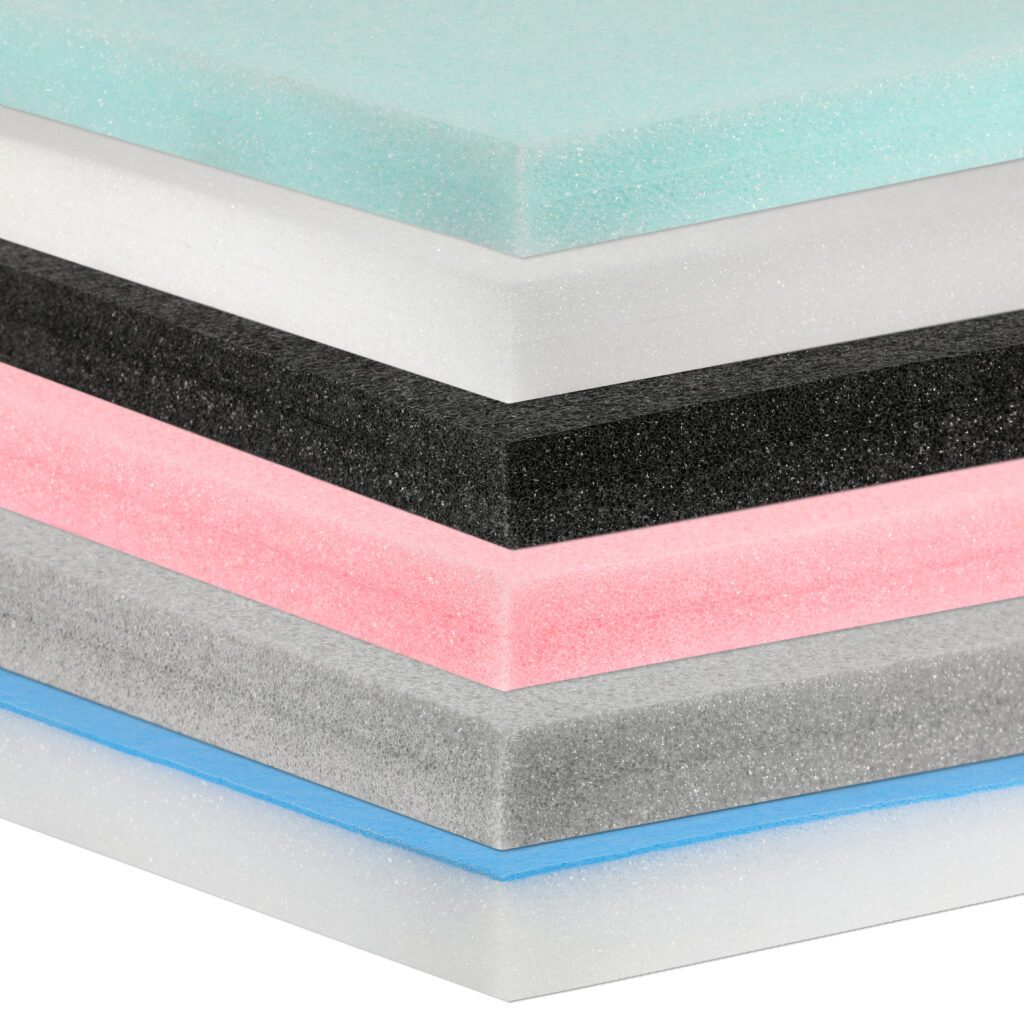

- Convoluted (Egg crate) foam

Lets get started!

Contact us today and our in-house design and manufacturing experts will review your needs to ensure the best fit for your project.